Process Description of a Diaphragm Wall made by Stein HT

[according to DIN EN 1538]

Preface/Fields of Application

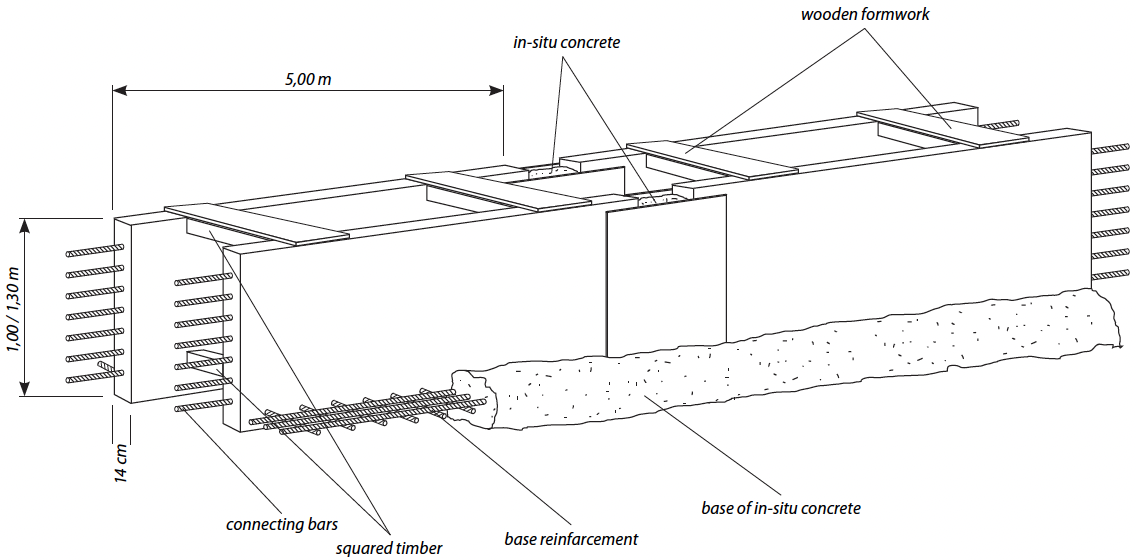

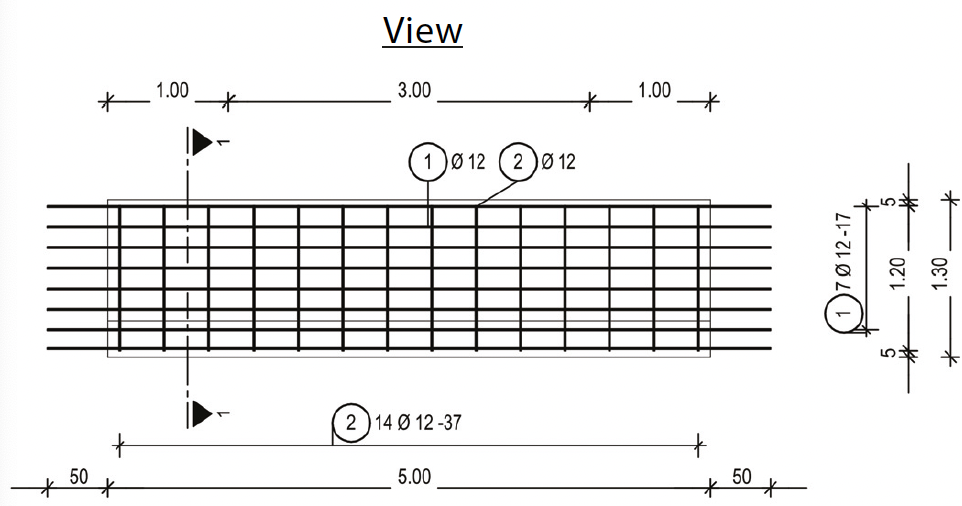

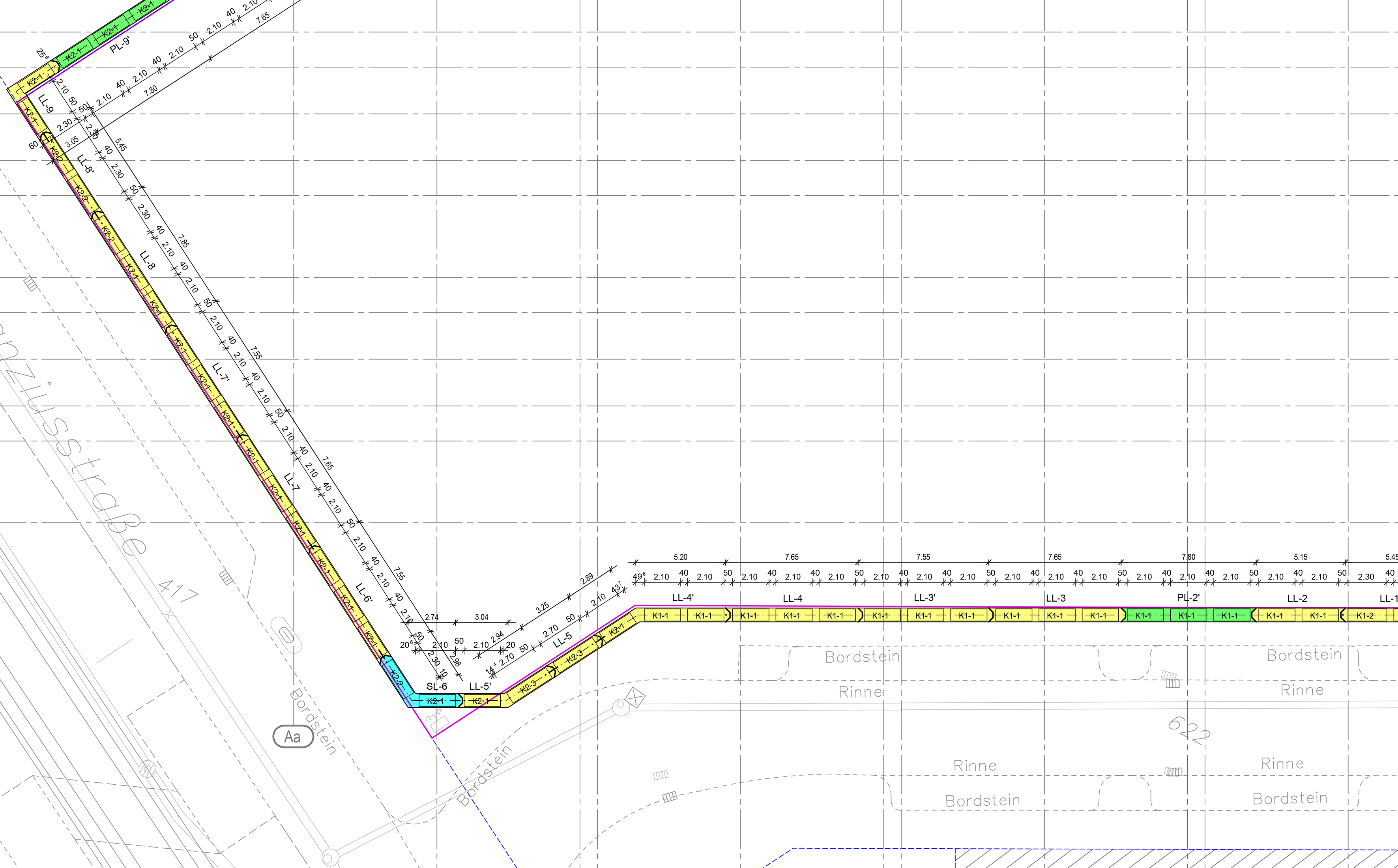

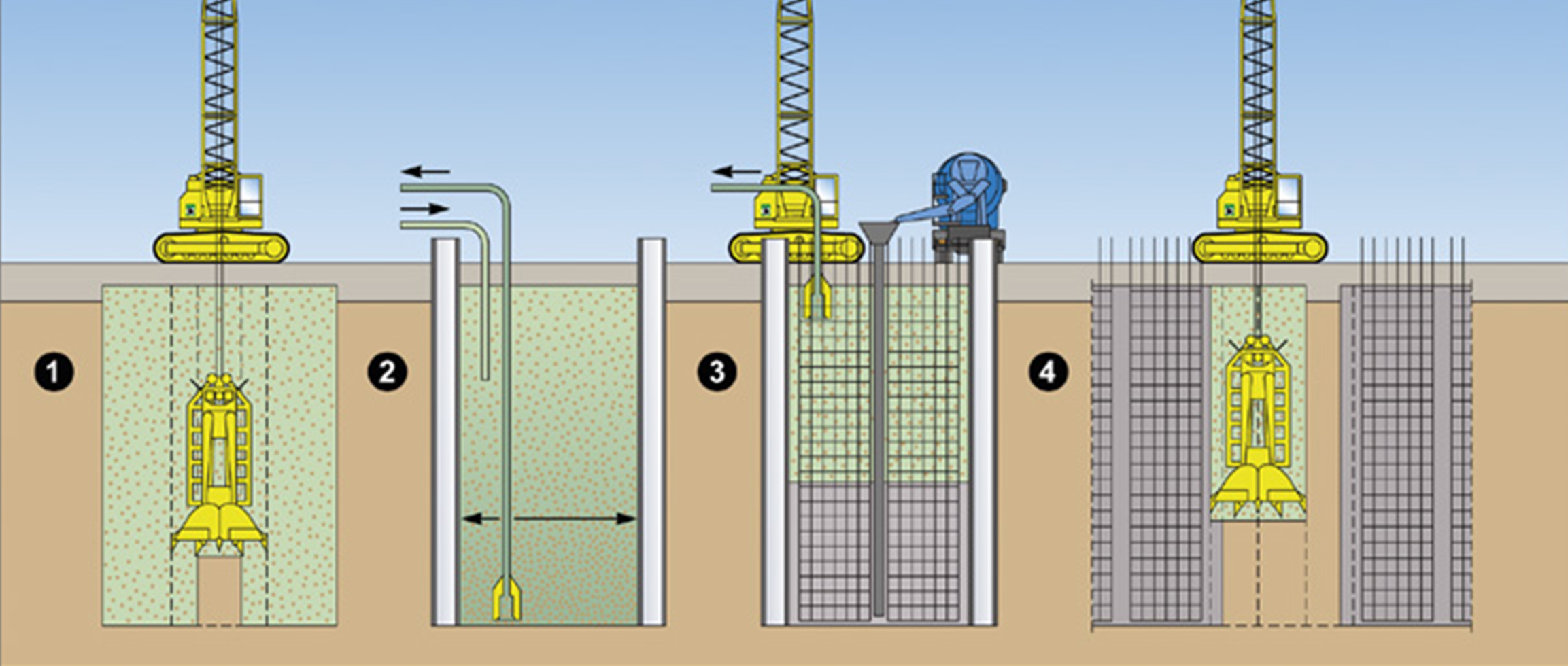

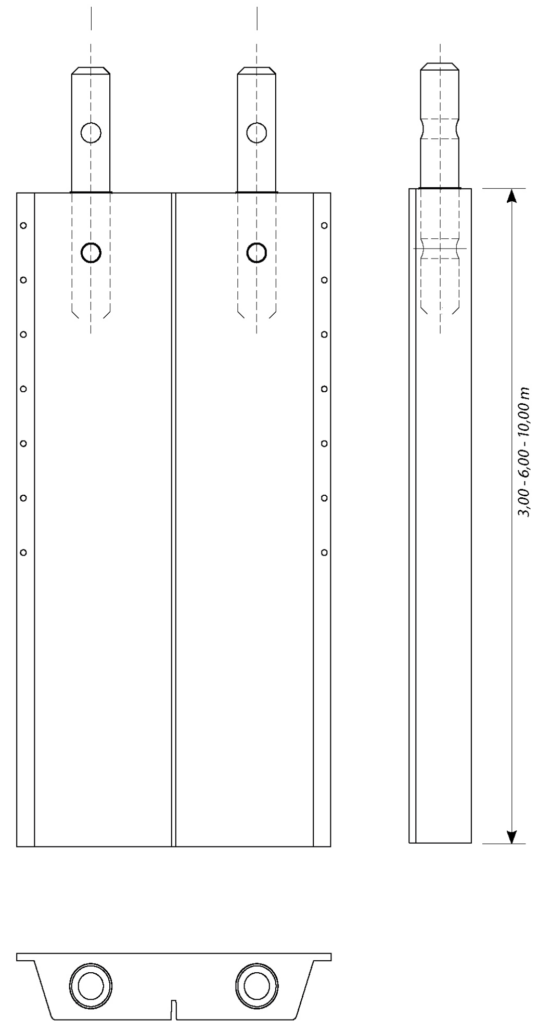

A diaphragm wall is a vertically executed reinforced concrete wall. It is excavated by means of supporting suspension and has a sealing effect. Both, as a temporary and as a permanent structure, it can also assume load-bearing/load-transferring functions. Wall thicknesses typically range from 600 mm to 1500 mm and depths of max. 40 m are usual, although thicknesses of max. 2000 mm and considerably deeper walls are feasible.

A diaphragm wall is usually (but not exclusively) used for the following structures:

- Tunnel and underground construction

- Enclosure/stabilisation of building pits

- Pipe jacking shafts

- Underground car parks

- Inner-city building pits

- sluices

- Landfill enclosures

- As foundation element (barrettes)

The advantages of a diaphragm wall in comparison to other foundation processes are as follows:

- Low-noise and low-vibration construction

- Low deformation

- In case of adequate statics, it can bear very high loads

- Shorter construction period in comparison to e.g. bored pile walls

- Sealing effect